TTK Project Case Study: TTK at Taiwan Semiconductor Manufacturing

TTK WATER AND OIL LEAK DETECTION SYSTEMS

AT

TAIWAN SEMICONDUCTOR MANUFACTURING, TAIWAN

View the case study in PDF format.

Project Background

For almost a decade, TTK systems have been installed in and protect numerous manufacturing sites of TSMC via our local partner. Some of these sites include: 12-inch Wafer Gigagfabs, Fab12,

Fab14, Fab15, Fab18, Backend Fabs, Advanced Backend Fab 2 and Fab5.

Within these sites, the main areas being protected are:

- Areas equipped with a raised floor, such as HPM area and laboratory;

- Areas equipped with a false ceiling and sprinkler pipes;

- The diesel day tanks.

image not clear of engineer working in white gloves using a microscope for examination a silicon wafer, Reflection light and blurred background

Project requirements

- Process Chilled Water Systems (PCWS) circulate process water to the application’s point of use and back again, allowing for efficient use of water-cooled machines. Whilst essential to the

operation of many processes within microprocessor industry, water also presents a major potential source of a leak inside a cleanroom. A reliable locating water leak detection system

capable of detecting multiple simultaneous leaks is required to protect numerous PCWS. - A specific water sense cable for horizontal sprinkler pipes application, capable of keeping water in place around it to ensure an efficient detection.

- The client also requires a small fuel leak detection system to monitor a few day tanks.

TTK’s Solution

- The digital water leak detection system – the FG-NET monitoring panels with over 50 lengths of FG-EC addressable water sense cables – is installed inside the 12” Giga Fab (see an exeample of the schematic). The integration with FMCS (Facility Monitoring Control System) is through RS-485 Modbus.

Differing from the analog sense cables, each length of FG-EC cable contains an embedded microprocessor which intelligently monitors the cable status and provides continuous real-time communication to the FG-NET panels. Moreover, its highly visible LED (placed on the female end connector) provides quick identification of the cable status, which is extremely helpful for technicians working in the dark environment under the false floor.

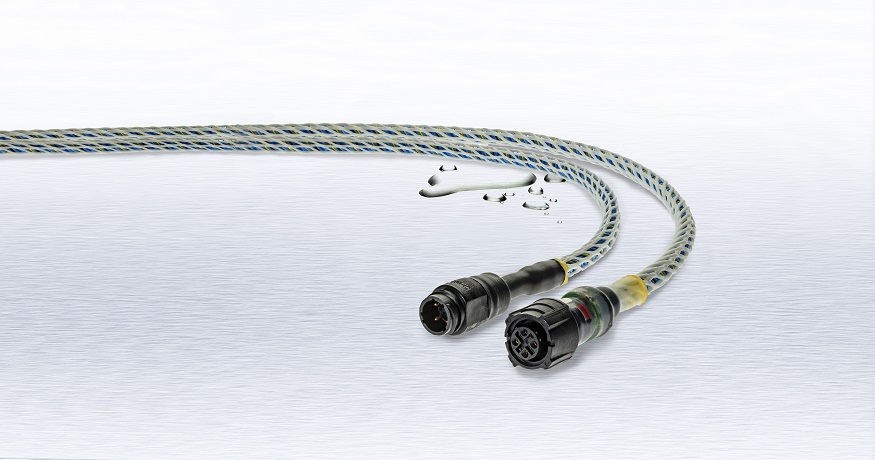

- To protect the horizontal sprinkler pipes above the false ceiling, the addressable water sense cable with braid (FGECB) is adopted. Perfoming the same function as FG-EC digital sense cable, this cable is specifically designed for pipe applications, since it is equipped with an external polyethylene based braided jacket surround which keeps the liquid in place around the cable.

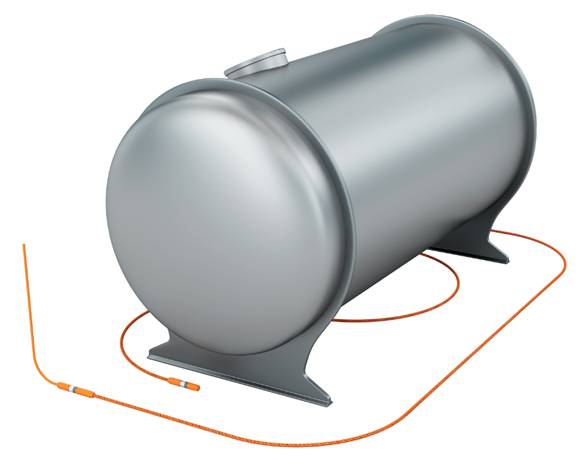

- For diesel leak detection, we recommend the fuel monitoring unit FG-ALS4-OD with the re-usable FG-OD oil sense cable be installed to the perimeter of each day tank.

Diesel is a low volatile hydrocarbon liquid and the FG-OD cable can detect it within just 35 minutes (a great deal faster than the 120 minutes of traditional sense cables).